DC motor has fast response, large starting torque, from zero speed to rated speed with the performance of providing rated torque. We know that brushless DC motor in many occasions not only requires good starting and adjusting characteristics of the motor, but also requires the motor to be able to reverse and forward. How to realize the positive and negative rotation of Brushless DC motor? Please see below.

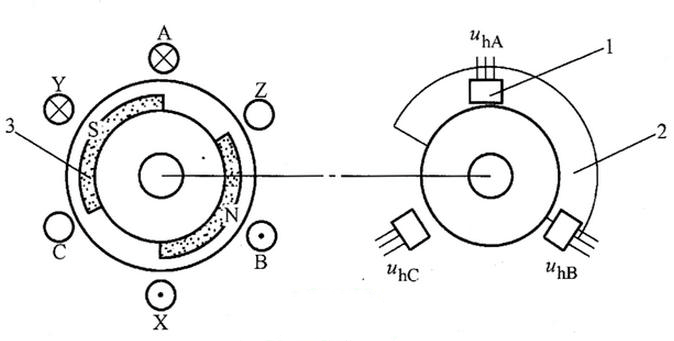

In order to realize the motor's positive and negative inversion, it is usually adopted to change the logic relation of the inverter's switching transistor and make the sequence of the armature windings change. In order to produce the maximum average electromagnetic torque to ensure symmetrical operation, it is necessary to design the relationship between the rotor position sensor and the main pole of the rotor and the windings of the stator.

Positive / negative control (DIR)

The operation direction of the motor can be controlled by controlling the connection of terminals "DIR" and terminal "COM". The terminal "DIR" is pulled up to +12 by resistance, which can be used with passive contact switch or PLC and other control units with collector open circuit. When "DIR" and terminal "COM" are not connected, the motor runs clockwise (facing the motor shaft), otherwise it runs counter-clockwise; in order to avoid DC brushless driver. Damage, when changing the motor steering, the motor should stop moving before operating to change the steering, to avoid the motor running direction control.

Speed signal output (SPEED)

The DC brushless driver provides a pulse signal proportional to the motor speed through the terminal SPEED~COM. The number of pulses per turn is =6 x motor polar logarithm, SPEED frequency (Hz) = the number of pulses per revolution * speed (R / min) 60. Example: 4 pair pole motor, 24 pulses per revolution, when the motor speed is 500 rpm / min, the terminal SPEED output frequency is 200 Hz.